Carbon fiber is widely used, an article to explore its advantages and disadvantages, types, processes and applications

Carbon fiber is the most important inorganic high performance fiber, which is determined by its material nature, industrial technology complexity, importance of application areas and market scale, etc. Its first market application was a carbon fiber reinforced resin fishing rod marketed in 1972. Since then, carbon fiber applications have rapidly developed to the high-end represented by the main structural materials of aerospace vehicles.

In early 2017, Toray launched a new generation of carbon fiber prepreg for the aerospace market, which is said to have the best performance in the world, with a 30% increase in tensile strength and impact resistance over its predecessor. The product solves the long-standing technical problem that high modulus and high toughness cannot be combined, and can withstand temperature extremes (very high and very low temperatures), carbon fiber and its products are deeply applied to all areas of human life with its excellent performance.

01 What is carbon fiber prepreg

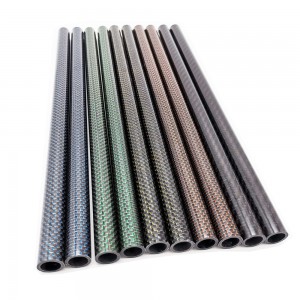

Prepreg (Preimpreg, PreimpregnatedMaterials), is a prepreg sheet product made by impregnating the matrix (Matrix) in reinforced fiber (Reinforced Fiber), which is the intermediate material of the composite material, also known as carbon fiber prepreg fabric. Carbon fiber prepreg is a composite material made of reinforcement, such as carbon fiber yarn, resin matrix, release paper and other materials, processed by coating, hot pressing, cooling, laminating, rolling and other processes, also known as carbon fiber prepreg

02 Advantages and disadvantages of carbon fiber prepreg

High strength and low density: the strength of carbon fiber prepreg can reach 6-12 times that of steel, and the density is only one quarter of steel.

Good plasticity; can be made into any shape according to the shape of the mold, easy to shape and easy to process.

Corrosion resistance; long life.

The advantages of large filament bundle carbon fiber prepreg in the industrial field are highlighted. Unidirectional carbon fiber prepreg surface density up to 600 g/m2, this kind of thick prepreg greatly improves the efficiency of prepreg and subsequent lay-up process. It has a wide range of applications in the wind power blade and automotive fields.

The non-hot pressed can process (OOA, Out of Autoclave) prepreg is strongly developed. This molding process significantly reduces the time and cost of subsequent curing and molding of prepregs. These new prepregs can be made using the lower cost vacuum bagging, advanced pultrusion and hot molding methods. Products such as Hexcel’s HexPly®M 56, Tencate’s TC 250, Cytec’s Cycom 532, and ACG’s MTM 44-1.

Different prepreg product forms appear. Short-cut prepregs, which can be economically molded, such as Hexcel’s Hexmc, Dencate’s MS series; semi-prepregs, which do not require complete “wetting” of the fibers during the prepreg process and complete infiltration during the subsequent process, such as Hexcel’s Hexfit.

Special prepregs for different applications. For example, in the automotive industry, where the short time required to form parts is high, a fast curing prepreg of <5 min must be developed to meet the subsequent rapid forming process, such as Hexcel’s Hexply M77, which can be cured in 2 min at 150 °C.

Gurit has developed SparPregTM to obtain low porosity laminates without compaction and with the help of other exhaust fabrics; in the field of composite molds, various companies have also developed corresponding prepreg products, such as Hexcel’s Hextool and ACG’s DFormTM specialty products.

Prepregs that combine structure and function. Carbon nanotubes or short-cut carbon fibers are mixed into the resin and then infiltrated with carbon fiber tows or fabrics to form a prepreg with wave absorption function.

Prepreg co-cured with other materials. The prepreg can be cured with the infused resin, molded with SMC, or molded with one-way prepreg, fabric prepreg, and SMC. The above are all about thermosetting carbon fiber prepreg, in fact, in recent years, the rapid development of foreign thermoplastic prepreg, such as: Germany Cetex Institute is engaged in textile semi-finished products, functional parts and high-performance structure of the manufacturing technology and equipment research and development institute, it is attached to the German Chemnitz University of Technology. The institute’s Ce-Preg® thermoplastic prepregs are fiber composite semifinished products made of continuous fibers laminated with thermoplastic films. Compared to thermoset prepregs, thermoplastic prepregs do not require cold storage and transportation, the subsequent molding process is efficient and convenient, the material is tough and has good impact resistance, and it is especially recyclable, which is in line with the green trend of energy saving and environmental protection. However, there are four major problems with thermoplastic prepreg.

First, the high viscosity of the thermoplastic resin leads to very difficult infiltration with the fiber.

Second, there is no suitable low-cost, efficient and quality-assured prepreg preparation methods and equipment.

Third, the molding temperature of high performance thermoplastic resin is above 350 ℃, and the molding process of prepreg and its composite products is very difficult.

Fourth, high-performance thermoplastic resins are too expensive compared with general-purpose thermosetting resins.

At present, the international mainly through powder coating, fiber blending, film rolling and other processes to obtain different resin quality fraction precision of thermoplastic prepreg, respectively, to meet the needs of various molding applications

Post time: Nov-19-2022