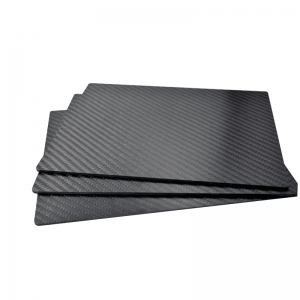

Introduce you to carbon fiber

Carbon fibers can be divided into small bundles and large bundles according to their size. An important indicator of carbon fiber is the number of single fiber roots contained in each bundle: Small bundle carbon fiber usually refers to the fiber bundle with the number of carbon fiber roots less than 48,000 (excluding 48,000), including 1K, 3K, 6K, 12K, 24k, etc. It is mainly used in high-end technology fields such as national defense, military industry, aerospace and so on, with low output, high cost, and high price, so it is called “astronaut-grade material”. Large bundles of carbon fiber, usually refers to the number of carbon fiber roots of 48,000 namely 48k or above fiber bundles, including 48K, 50k, 60K, widely used in textile, medicine and health, mechanical and electrical, civil construction, transportation and energy and other industrial and civil fields, low cost, but difficult to control production, known as industrial grade materials.

Two – step polymerization method and wet spinning method are used to produce large carbon fiber bundles. In the process of carbon fiber preparation, the preparation process of profilaments is the key to determine the properties of carbon fiber. Two important steps of profilament are polymerization and spinning. Polymerization is the polymerization of acrylonitrile monomer into spinning solution. Spinning determines the performance of profilament. Polymerization can be divided into one-step method and two-step method according to different processes. One-step method with high polymerization conversion and short process is mainly used for small strands, while two-step method is more suitable for large strands. The spinning process is divided into dry method, wet method and dry and wet method. The large silk bundle mainly adopts the wet process: the polymer is dissolved in solvent, the fine stream is sprayed through the spinneret, into the solidification bath to form the fiber, and finally the primary fiber is rolled or directly processed. The wet process costs less but spins at a slower rate

Post time: Mar-06-2023